The question we are setting out to answer is, how Computer-Aided Design (CAD) and 3D printing are revolutionizing the jewelry industry faster than you can say “Diamonds are forever.” Or should we now say, "Diamond designs are just a click away"? And we mean jewelry design in general, and not only with diamonds.

Let's explore CAD jewelry creation with the help of CAD.

Traditional Jewelry Making

Let's take a stroll down memory lane. Picture this: a smoky workshop filled with the scent of molten metal, artisans hunched over intricate pieces, painstakingly bending and shaping the material. You’d find jewelers working like sculptors, carving intricate pieces of jewelry from a wax block. The traditional method often included techniques like casting, molding, and good old-fashioned hammer-and-chisel craftsmanship. It was a labor of love, emphasis on the "labor." In traditional jewelry making, a a hand-carved wax model often serves as the starting point, which is then used for casting the precious metal. All in all, it was, and still is, an incredibly intricate process.

Sure, these age-old methods have an undeniable romantic appeal. But here’s the reality check: these traditional methods were slow, required the mastery of complex skills, and left little room for error. Imagine working for days on a piece, only to discover that it looks less like a "masterpiece" and more like "modern art gone wrong." Yeah, not fun. And let’s not even talk about scaling up production; it’s like asking a snail to compete in a sprint.

CAD and 3D printing have revolutionized the jewelry industry, bringing a new vision to the craftsmanship and design possibilities.

The Advent of CAD and 3D Printing

Enter CAD and 3D printing, stage right, with a Broadway-level entrance that’s hard to ignore. This isn’t just a flashy newcomer; it’s a game-changing revolution! But when did CAD and 3D printing first decide to join the jewelry party? Well, CAD has been around in other industries since at least the 1960s. It took a while for this technology to get glammed up and mingle with the diamonds and sapphires, but when it did—oh boy, it was a match made in heaven.

3D printing, the younger sibling, also made its grand entrance, initially to create prototypes but soon proving it could be the star of the show. With these technologies, designs could be created and altered digitally, prototypes could be printed in a jiffy, and intricate designs could be executed with the precision of a surgeon. It’s as if the jewelry industry got a technological facelift, and let me tell you, it’s looking fabulous.

Today, CAD and 3D printing don't just occupy a niche corner of the jewelry world. They’re front and center, taking the lead role in a performance that’s still unfolding. And we couldn't be more excited to see what the next act brings!

What is CAD?

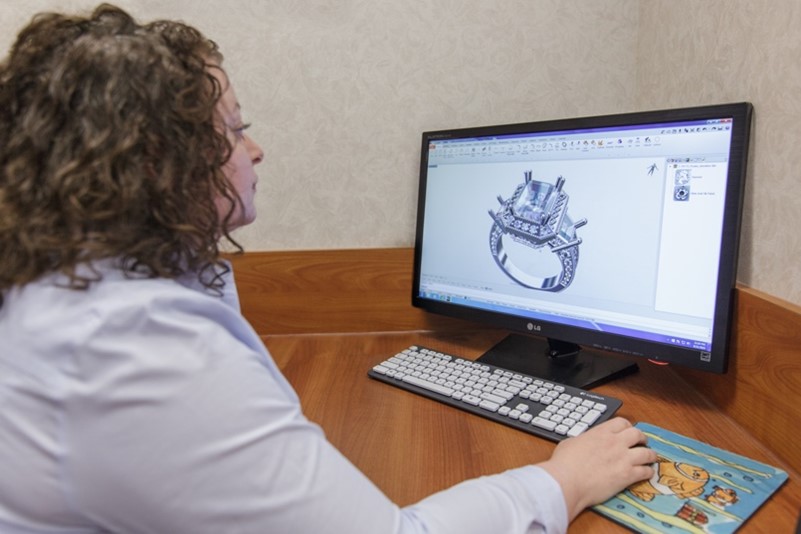

Okay, folks, gather around. It's story time! Once upon a time, jewelers used to sketch out their designs on paper. Yes, you heard me, paper—made from trees and everything! Fast-forward to today, and we’ve got CAD, or Computer-Aided Design, that makes those paper sketches look like kindergarten doodles. CAD lets you create a 3D model of your jewelry design on a computer. The software is so intuitive that if it were any smarter, it’d make your morning coffee and walk your dog.

Okay, folks, gather around. It's story time! Once upon a time, jewelers used to sketch out their designs on paper. Yes, you heard me, paper—made from trees and everything! Fast-forward to today, and we’ve got CAD, or Computer-Aided Design, that makes those paper sketches look like kindergarten doodles. CAD lets you create a 3D model of your jewelry design on a computer. The software is so intuitive that if it were any smarter, it’d make your morning coffee and walk your dog.Here’s the 411: With CAD, you get to mess around with different shapes, sizes, and configurations until you hit the jackpot. Need to rotate that model to get a 360-degree view? Done. Want to zoom in so close you can see the digital sparkle? Absolutely. It’s like a video game, but instead of slaying dragons, you're creating wearable art. The real beauty of CAD is its accuracy and precision. You can tweak your designs down to a fraction of a millimeter. Yeah, that’s right, a fraction of a millimeter. Eat your heart out, traditional methods!

What is 3D Printing?

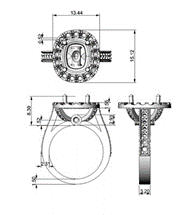

Hold onto your gemstone-encrusted hats, because if CAD was the appetizer, 3D printing is the main course with dessert rolled into one. Imagine you’ve created this stunning design using CAD. Now what? Do you hand it over to an artisan and wait patiently while they chisel away? Nope! You send that file to a 3D printer, and voila, you’ve got a prototype—or even the final piece—ready for being cast in any metal. ”

Hold onto your gemstone-encrusted hats, because if CAD was the appetizer, 3D printing is the main course with dessert rolled into one. Imagine you’ve created this stunning design using CAD. Now what? Do you hand it over to an artisan and wait patiently while they chisel away? Nope! You send that file to a 3D printer, and voila, you’ve got a prototype—or even the final piece—ready for being cast in any metal. ”But wait, there’s more! There are different flavors of 3D printing to savor. Fused Deposition Modeling (FDM) works by layering material on top of material. It's like making a multi-tiered cake, but less edible and more valuable. Stereolithography (SLA) uses a laser to cure a liquid resin into the desired shape. Think of it as the sorcery of jewelry making. Digital Light Processing (DLP) is another technique that’s similar to SLA but uses a digital light projector screen instead of a laser. It’s the 3D printer’s way of saying, “Let there be light—and then, let there be jewelry!”

In all these methods, the printer translates your digital design into a physical object by adding layer upon layer of material. It’s like building a sandcastle one grain at a time, but a lot faster and minus the sunburn.

For jewelry designers, CAD and 3D printing have become invaluable tools, making the design process not only more efficient but also more precise.

How CAD and 3D Printing Expand Design Possibilities

Intricate Designs

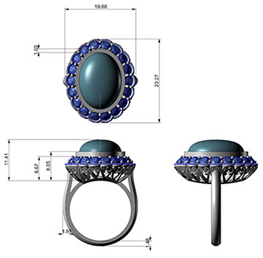

Let's get one thing straight: intricate designs in jewelry are like the frosting on a cake. Sure, you could eat the cake plain, but why would you when you can have delicious, ornate swirls of buttercream? That’s where CAD comes in, providing jewelers the digital tools to create incredibly detailed designs without resorting to arcane rituals or chants to the Jewelry Gods. You can include spirals, loops, filigrees, and engravings that look like they were crafted by a miniature Michelangelo with the steadiness of a neurosurgeon.

In the pre-digital era, attempting to handcraft these details was a venture into dangerous territory. One false move, and your beautiful piece could end up looking like it got hit by a truck. With CAD and 3D printing, even the most intricate of designs can be produced consistently, and without the need for an emergency rescue operation.

CAD software allows for unparalleled precision, opening the doors for jewelers to create any unique design with intricate details that were nearly impossible to achieve by hand. Imagine not having to go through multiple iterations and adjustments just to get the center stone perfectly placed; with 3D printing, what you see on screen is what you get in real life.

Customization

If you've ever played with building blocks as a kid (or as an adult, we're not judging), you know the joy of creating something uniquely yours. Customization in jewelry is basically the grown-up, glitzy version of that. Forget about flipping through a catalog of designs that you can only dream of altering. CAD and 3D printing are the superheroes of customization, swooping in to rescue you from the jaws of mass-produced monotony.

And with an online design tool which many jewelers offer as a service, you can tweak and visualize every aspect of your dream ring before sending it off to the 3D printers. It doesn't get much easier than that!

The advent of CAD and 3D printing technologies means you're no longer limited to what you find in store showcases; you can actually design your own ring down to the tiniest detail. In a market saturated with similar-looking engagement rings, for example, CAD and 3D printing offer the refreshing opportunity to design a unique, one-of-a-kind engagement ring.

Whether you’re a hopeless romantic looking to incorporate initials and birthstones into a necklace or a trendsetter keen to make a unique statement, the sky is no longer the limit—it’s just the beginning.

You can change gemstone placements, tweak the thickness of the band, or even create asymmetrical designs that would make Salvador Dalí tip his melting clock in approval. Gone are the days when engagement rings came in a few cookie-cutter designs; thanks to CAD and 3D printing, couples can now create rings that are as unique as their love stories.

Iteration and Prototyping

Remember etch-a-sketches? You’d twist and turn those knobs, but if you messed up? Tough luck! CAD and 3D printing, on the other hand, are the epitome of forgiveness and second chances. Got a design that's almost perfect, but not quite? No need to start from scratch, pulling your hair out in frustration. With a few clicks and adjustments, you can iterate as many times as you need.

Remember etch-a-sketches? You’d twist and turn those knobs, but if you messed up? Tough luck! CAD and 3D printing, on the other hand, are the epitome of forgiveness and second chances. Got a design that's almost perfect, but not quite? No need to start from scratch, pulling your hair out in frustration. With a few clicks and adjustments, you can iterate as many times as you need.And when it comes to prototyping, 3D printing offers you the joy of holding a physical model of your design without waiting weeks for it. With rapid prototyping, you can have a prototype in your hands faster than you can binge-watch the latest season of your favorite show. That means you can examine it, show it off, and—most importantly—make any necessary tweaks before the final production.

Lowering the Barriers to Entry

So, you've always wanted to launch your own jewelry line but thought you needed Scrooge McDuck levels of capital? Well, say hello to CAD and 3D printing, the ultimate financial wingmen in the jewelry industry. These technologies lower the barriers to entry by reducing the upfront costs associated with prototyping and production. Gone are the days when you needed to own a gold mine or be best buddies with a diamond dealer to get started.

So, you've always wanted to launch your own jewelry line but thought you needed Scrooge McDuck levels of capital? Well, say hello to CAD and 3D printing, the ultimate financial wingmen in the jewelry industry. These technologies lower the barriers to entry by reducing the upfront costs associated with prototyping and production. Gone are the days when you needed to own a gold mine or be best buddies with a diamond dealer to get started.Imagine not having to invest in expensive molds or hiring a small army of skilled artisans just to test a new design. With CAD and 3D printing, your startup budget can breathe easy. You could literally start a jewelry business from your garage—just don't forget to move the car out first.

Speeding Up Production

In the jewelry world, speed is not about racing through the design process like a caffeinated squirrel. However, efficiency is gold (pun intended). Traditional jewelry making can be as slow as molasses going uphill in January. CAD and 3D printing are like that rabbit in the race against the turtle—fast and accurate.

What does that mean for your bottom line? Well, quicker production times allow you to create more pieces and cater to more customers. Sticking with the example of rings, not only do these technologies make customized engagement rings more accessible, but they also speed up the production time, ensuring you're not waiting an eternity to pop the question. It’s Economics 101, but with more sparkles.

Bottom Line: because 3D printers can produce speedy prototypes, designers and buyers may cooperate more efficiently, revising designs before final products are manufactured.

Sustainability and Waste Reduction

We're all trying to be more eco-friendly these days, right? Well, guess what? CAD and 3D printing are basically the Captain Planets of the jewelry industry. These technologies are designed to use only the amount of material needed, reducing waste and making Mother Earth give you a nod of approval.

It's not just about using fewer raw materials; it's also about cutting down on energy consumption and pollution. In traditional methods, waste can be considerable, especially when dealing with precious metals and gems. With 3D printing, you can sleep easier knowing you're not turning the planet into a dumpster while crafting your treasures.

The savings on precious metal waste during the prototype phase alone make CAD and 3D printing economically beneficial for established brands and individual jewelers.

The Future of Jewelry Design with CAD/3D Printing

The future is looking brighter than a cubic zirconia under a spotlight. We're talking AI-driven designs, greater personalization, and maybe even AR (augmented reality)/VR (virtual reality) try-on features. Will there be 3D-printed jewelry on Mars? Who knows, but we're ready to push the boundaries of impossible!

The blending of traditional jewelry craftsmanship with CAD and 3D printing technology is as harmonious as peanut butter and jelly. It’s expanding our creative horizons, making things more economical, and adding a sprinkle of ethical goodness. These game-changing printing technologies are giving people the creative freedom to design their dream ring, even if they have little to no experience in jewelry design. Truly, the only limitations now are your imagination and perhaps the laws of physics. But mostly, your imagination.

Intrigued by this bejeweled revolution? Don’t just sit there like a cubic zirconia in a setting! CLICK HERE to explore our collection that proudly showcases the magic of CAD and 3D printing. And if you’re dazzled by the sparkle you see, make an appointment with our Jewelry Specialist today to discuss your next incredible jewelry purchase

CLICK HERE to learn more about CAD/3D Printing and broaden your horizons!

CLICK HERE to learn about how you can start a career in CAD from the comfort of your own home!